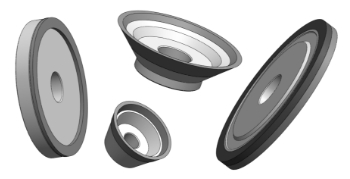

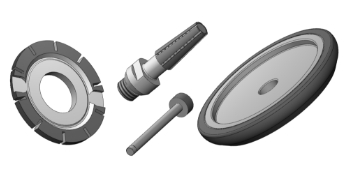

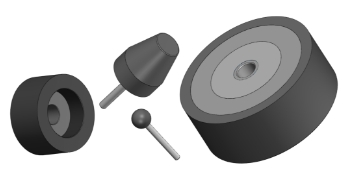

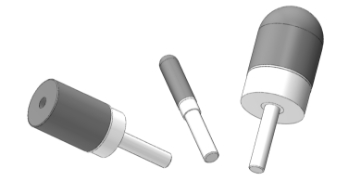

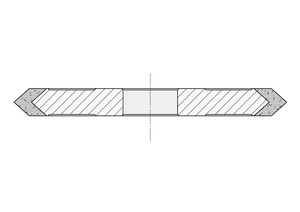

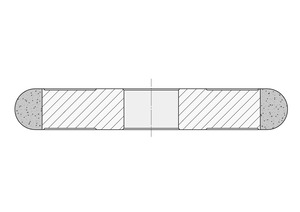

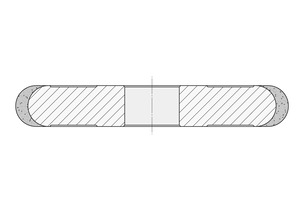

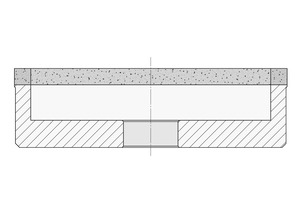

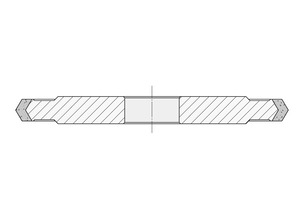

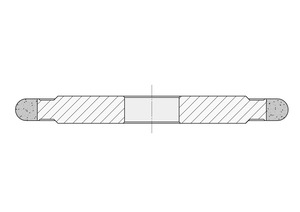

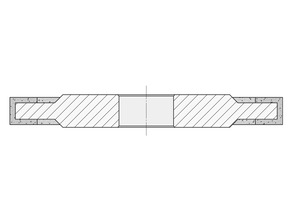

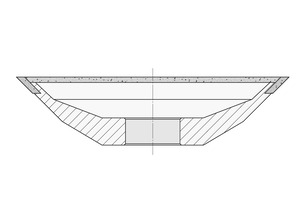

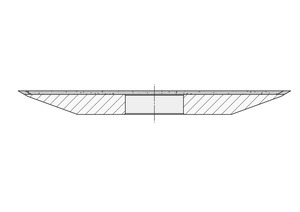

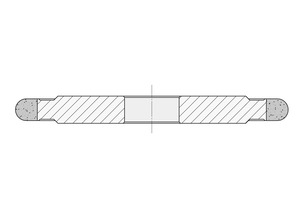

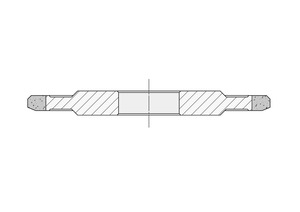

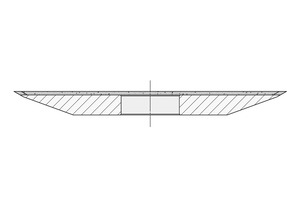

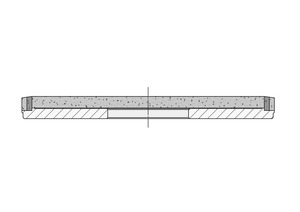

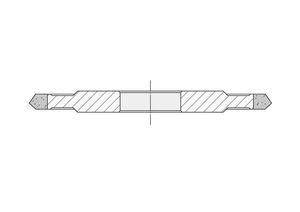

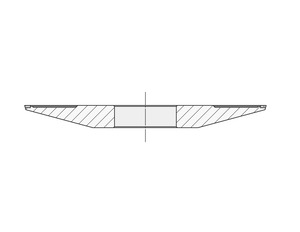

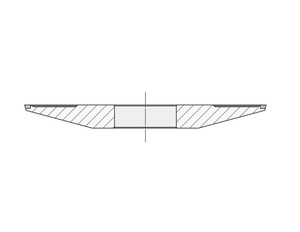

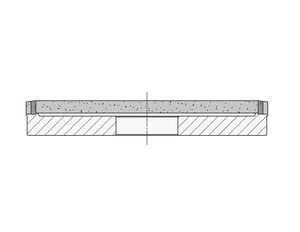

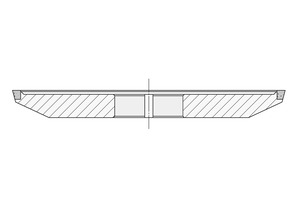

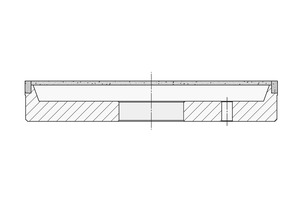

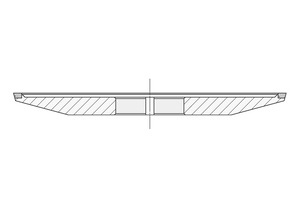

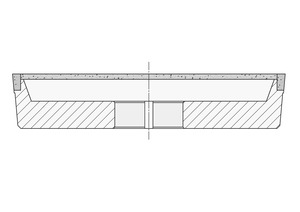

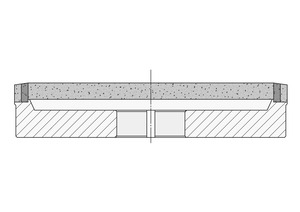

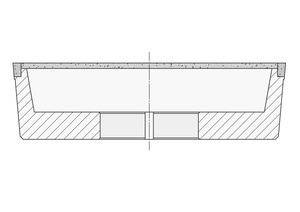

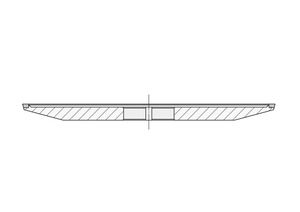

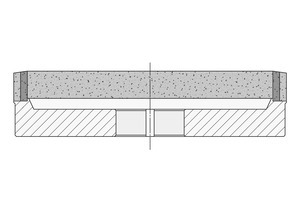

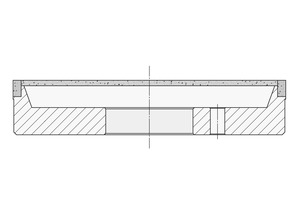

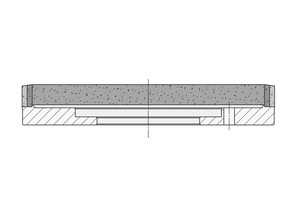

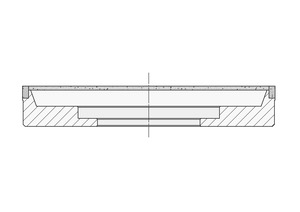

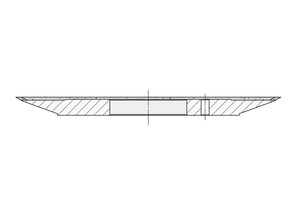

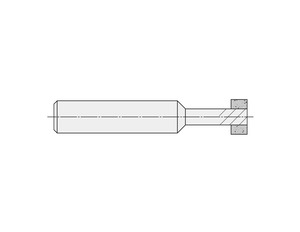

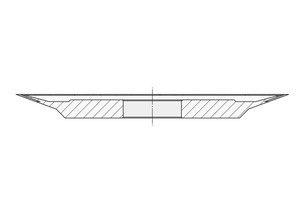

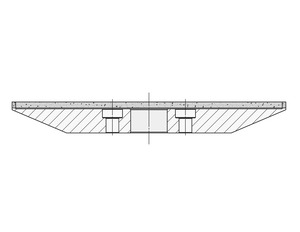

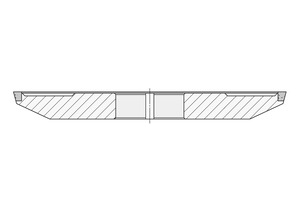

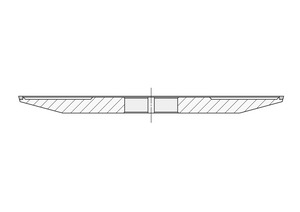

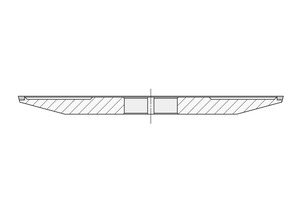

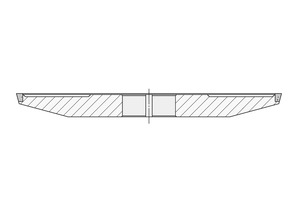

Grinding wheels in this category are made using a standard resin bond and a polyimide resin bond. The standard resin bond allows the wheel to be operated up to a temperature of approximately 180°C, while the polyimide bond can be used up to 350°C. If the processing temperature exceeds these values, a coolant should be used. For both of these product categories, diamond and CBN are used as abrasives.

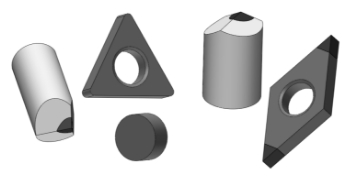

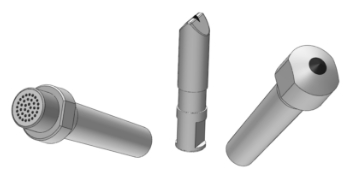

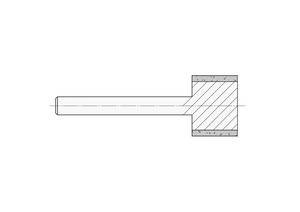

These grinding wheels are used for sharpening carbide cutting tools (HM) and high-speed steels (HSS). Due to a certain amount of elasticity of the resin bond, these grinding wheels show greater impact resistance.

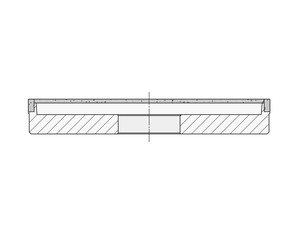

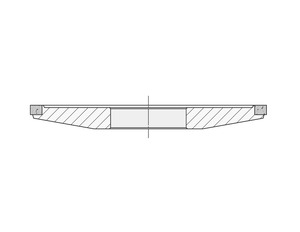

The main features of polyimide resin bonded wheels are:

– high working efficiency

– slow tool wear

– high temperature tolerance

– high wheel profile durability

– use of larger allowances when grinding

– long-term work on CNC machine tools

Search

Search Language

Language