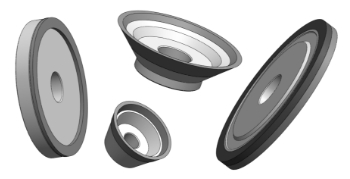

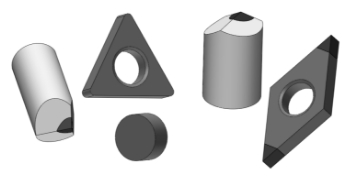

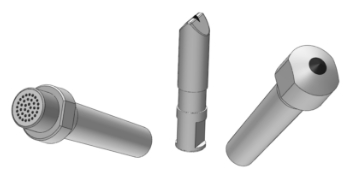

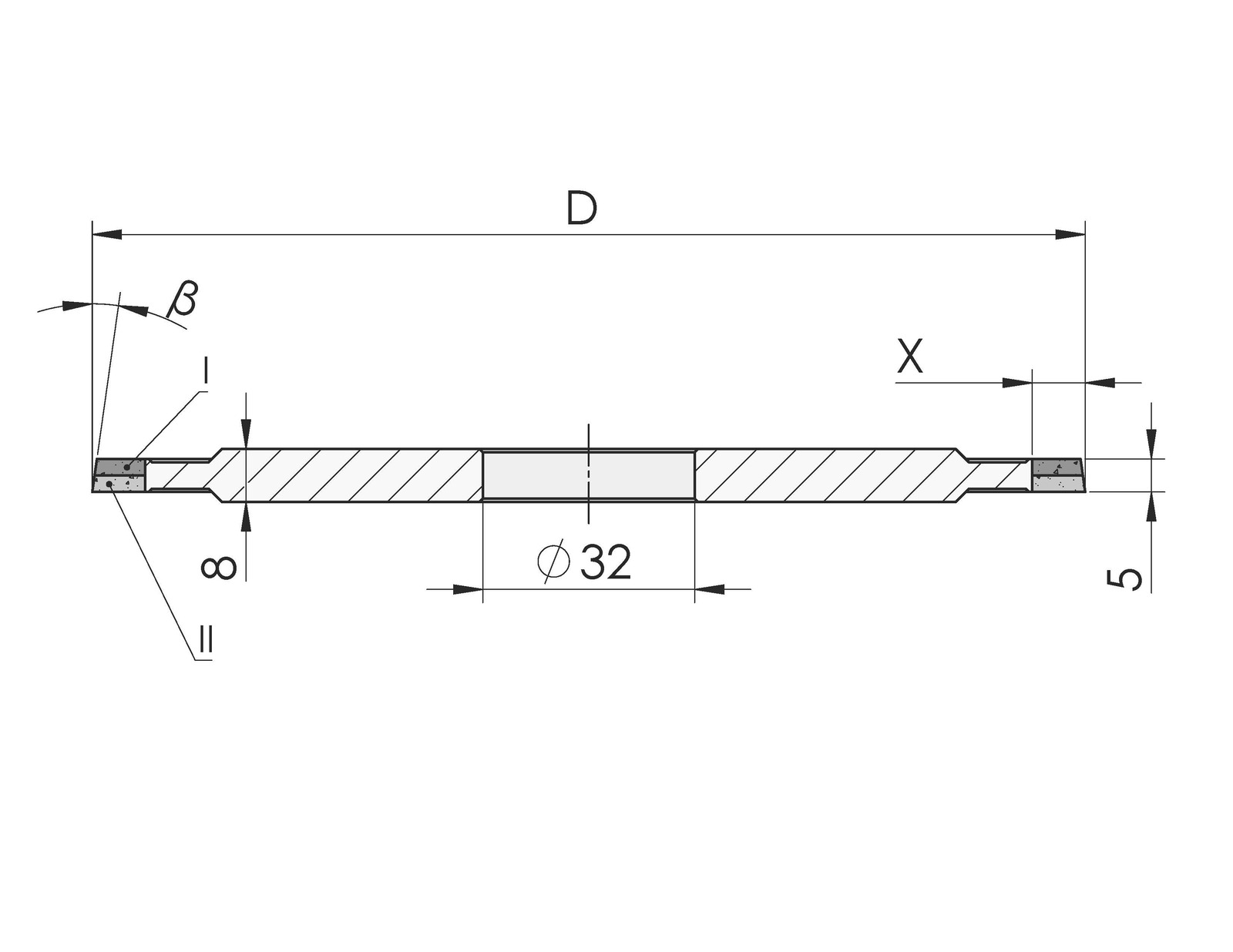

The two-layer grinding wheel, type 14AA1, is designed for sharpening the side surfaces of carbide-tipped circular saw blade teeth on Walter grinders like Woodtronic NC3 and NC4 (with a Ø 150mm wheel) as well as Woodtronic CNC5D (with Ø 175mm and Ø 200mm wheels).

With two abrasive layers, one with coarser grit (Layer I) and the other with finer grit (Layer II), it allows both rough and finishing grinding to be done in a single operation. This significantly reduces processing time and extends the lifespan of the sharpened tool.

Search

Search Language

Language