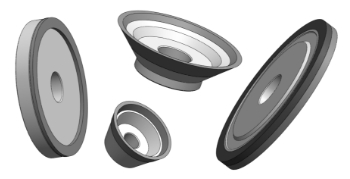

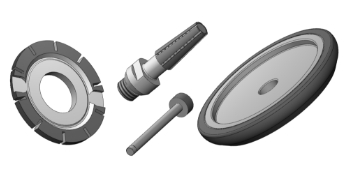

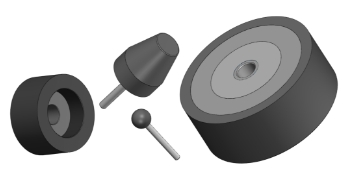

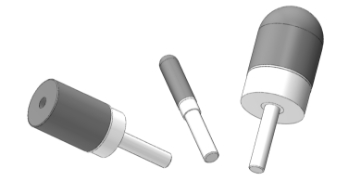

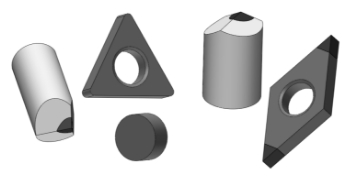

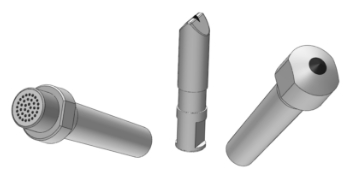

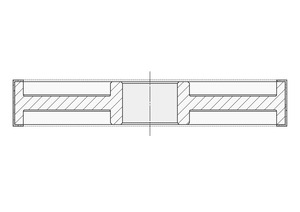

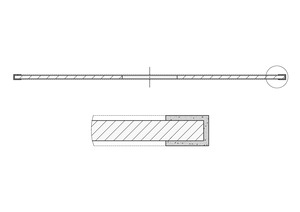

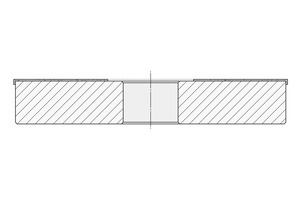

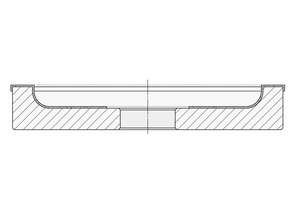

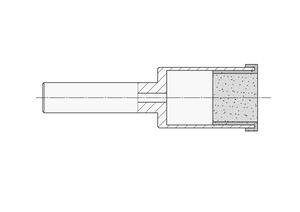

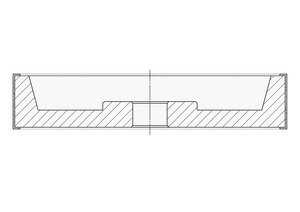

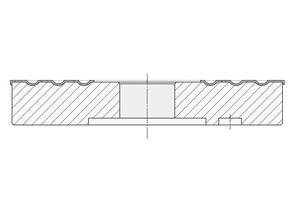

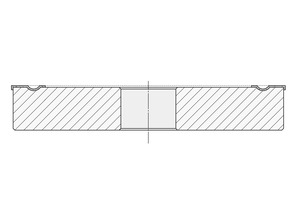

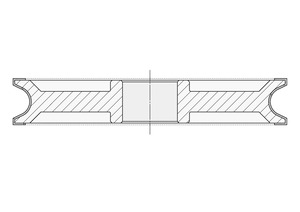

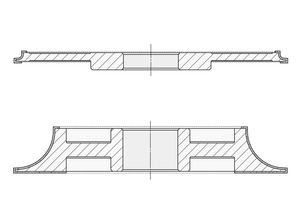

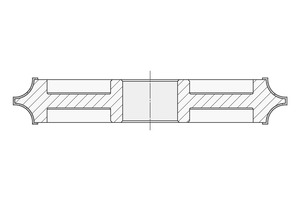

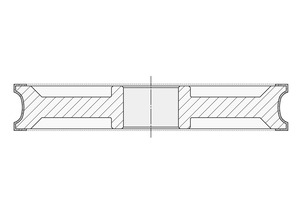

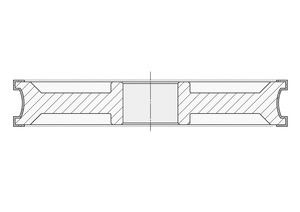

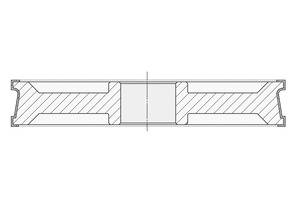

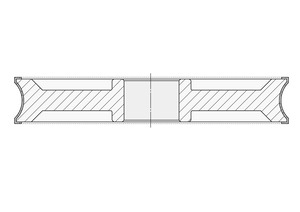

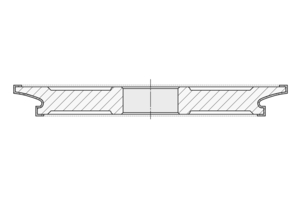

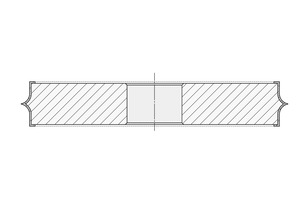

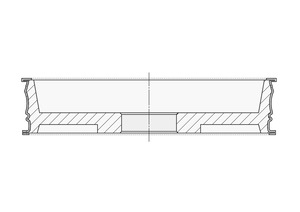

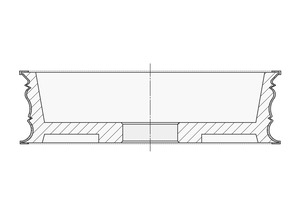

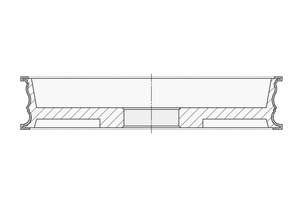

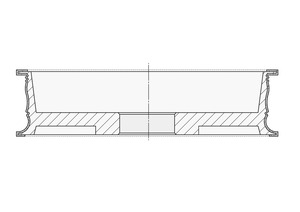

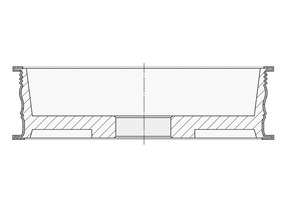

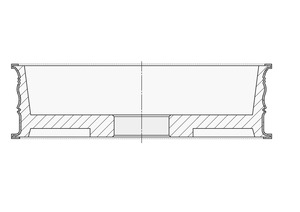

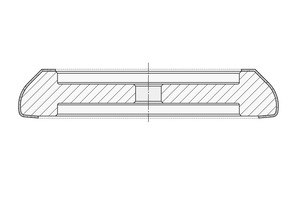

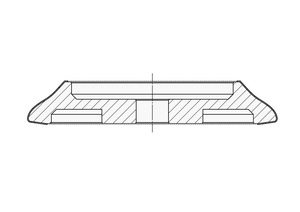

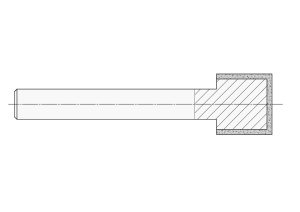

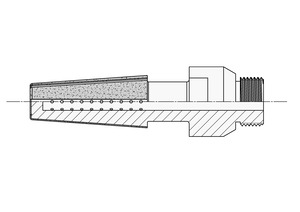

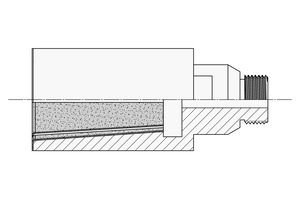

Electroplated grinding wheels use high-grade diamond and CBN as the abrasive. They are made on steel bodies, where the profile of the grinding wheel’s work surface reflects the exact profile of the workpiece. The grinding wheel profile contains a single layer of abrasive grit of the selected granulation, so that the wheel only works until this layer wears away, and thus no dressing is required. These grinding wheels can be reconditioned and their bodies can be used to reapply a new layer of abrasive grain. In this product category, we can produce discs with any profile according to the users’ needs.

These grinding wheels are used in the sharpening of WM, Fenes Standard, Lenox, and Roma band saws, amber, glass, plastics, concrete, medical prosthetic components, brake pads, for laminate boat manufacturing, and in many other industries.

The main advantages of galvanic bonded grinding wheels are as follows:

– long wheel life

– the possibility of machining workpieces with complex shapes with a single tool

– high machining accuracy

– low workpiece temperature

– no dressing required

– grinding wheels can be regenerated

Search

Search Language

Language