Application

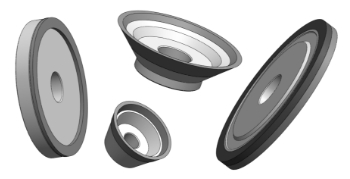

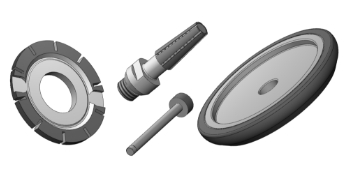

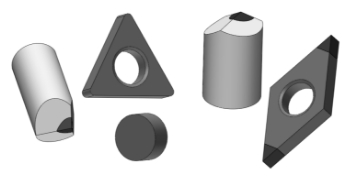

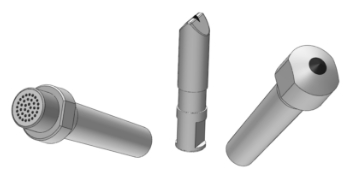

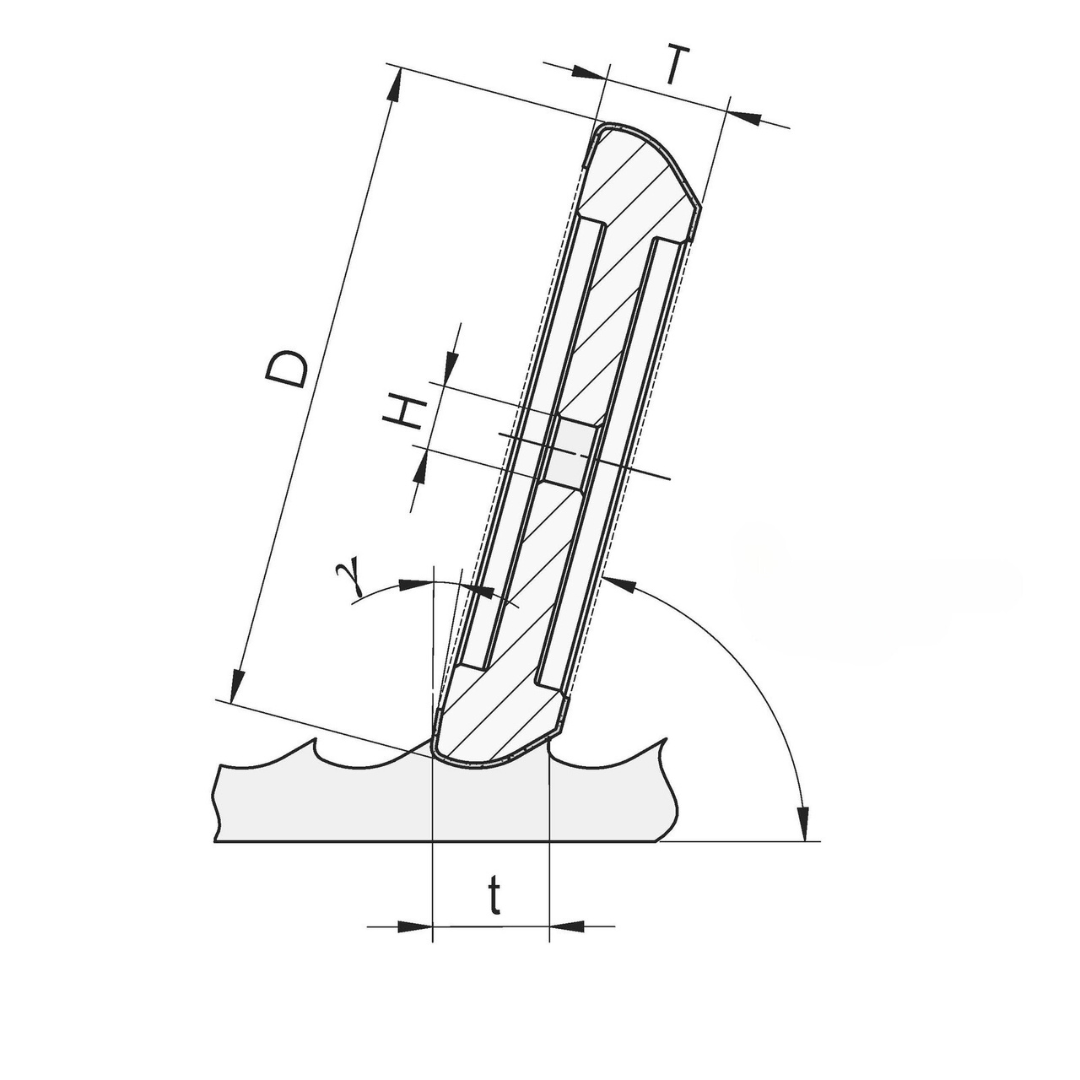

Profiled galvanic CBN grinding wheels PS are designed for sharpening band saws used in the woodworking, sawmill, and food industries. Thanks to the precise adaptation of the grinding wheel profile to the tooth profile, high repeatability of tooth geometry after sharpening is achieved, ensuring the long life of the saw.

Using galvanic CBN grinding wheels for sharpening band saws enables high efficiency without the risk of burning.

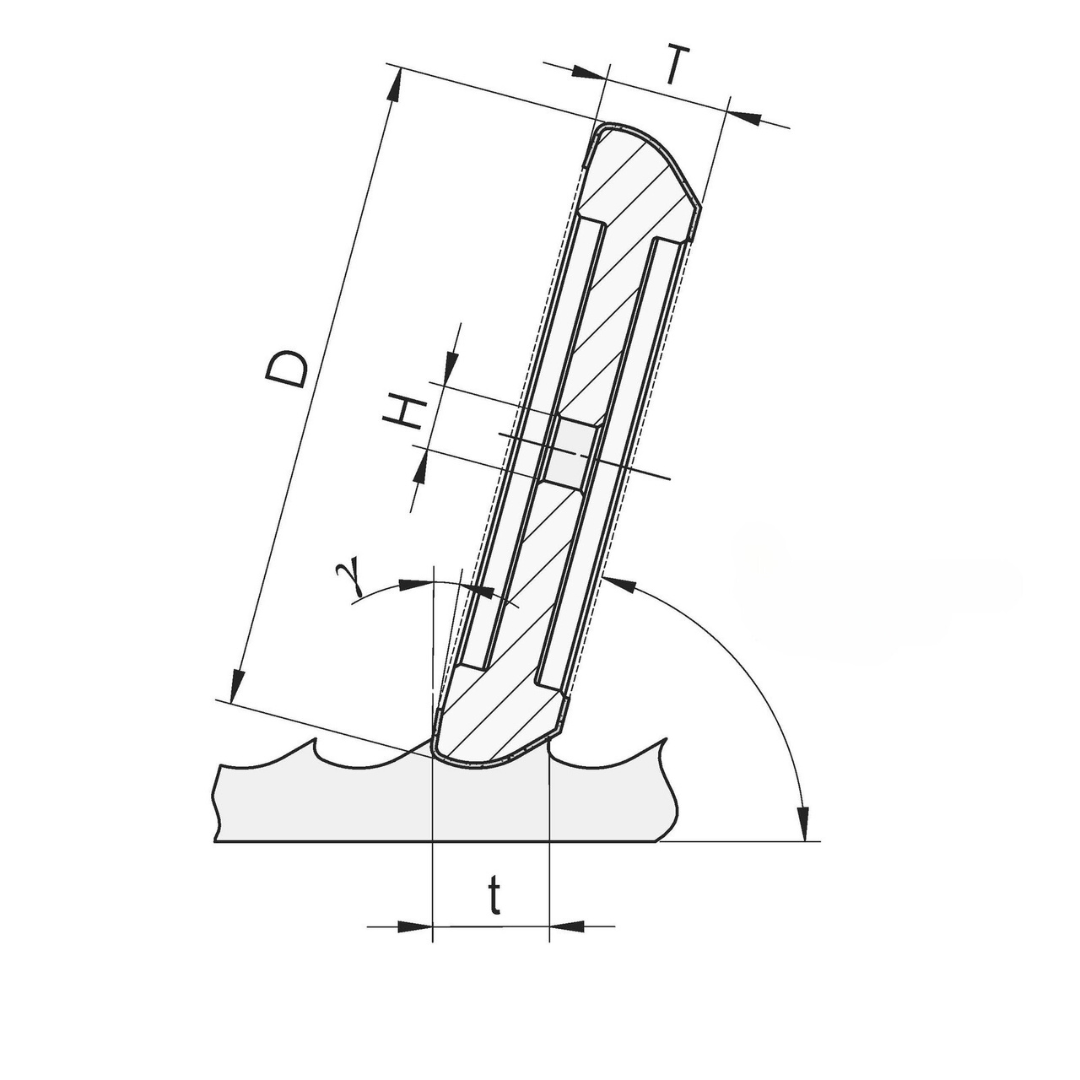

Dimensions

| Symbol |

γ |

t |

Notes |

Saw blade profile |

D |

T |

H |

| Fenes |

10° |

22,2 |

— |

Fenes Standard |

127 |

23,2 |

12,7 |

| Fenes |

10° |

22,2 |

— |

Fenes Standard |

127 |

23,2 |

20 |

| Fenes |

10° |

22,2 |

— |

Fenes Standard |

150 |

23,2 |

20 |

| Fenes |

10° |

22,2 |

— |

Fenes Standard |

203 |

23,2 |

25,4 |

| Fenes |

10° |

22,2 |

— |

Fenes Standard |

203 |

23,2 |

32 |

| WM |

10° |

22,2 |

Winter version |

WM 9/29 |

127 |

22,2 |

12,7 |

| WM |

10° |

22,2 |

Winter version |

WM 9/29 |

127 |

22,2 |

20 |

| WM |

10° |

22,2 |

Winter version |

WM 9/29 |

150 |

22,2 |

20 |

| WM |

10° |

22,2 |

Winter version |

WM 9/29 |

203 |

22,2 |

25,4 |

| WM |

10° |

22,2 |

Winter version |

WM 9/29 |

203 |

22,2 |

32 |

| WM |

10° |

22,2 |

Summer version |

WM 10/30 |

127 |

22,2 |

12,7 |

| WM |

10° |

22,2 |

Summer version |

WM 10/30 |

127 |

22,2 |

20 |

| WM |

10° |

22,2 |

Summer version |

WM 10/30 |

150 |

22,2 |

20 |

| WM |

10° |

22,2 |

Summer version |

WM 10/30 |

203 |

22,2 |

25,4 |

| WM |

10° |

22,2 |

Summer version |

WM 10/30 |

203 |

22,2 |

32 |

| WM |

10° |

22,2 |

For softwood |

WM 13/29 |

127 |

22,2 |

12,7 |

| WM |

10° |

22,2 |

For softwood |

WM 13/29 |

127 |

22,2 |

20 |

| WM |

10° |

22,2 |

For softwood |

WM 13/29 |

150 |

22,2 |

20 |

| WM |

10° |

22,2 |

For softwood |

WM 13/29 |

203 |

22,2 |

25,4 |

| WM |

10° |

22,2 |

For softwood |

WM 13/29 |

203 |

22,2 |

32 |

| Sword Lenox |

10° |

22,2 |

— |

Lenox |

127 |

22,2 |

12,7 |

| Sword Lenox |

10° |

22,2 |

— |

Lenox |

127 |

22,2 |

20 |

| Sword Lenox |

10° |

22,2 |

— |

Lenox |

150 |

22,2 |

20 |

| Sword Lenox |

10° |

22,2 |

— |

Lenox |

203 |

22,2 |

25,4 |

| Sword Lenox |

10° |

22,2 |

— |

Lenox |

203 |

22,2 |

32 |

| Ro-Ma |

10° |

22,2 |

Summer version |

Ro-Ma 8 |

127 |

22,2 |

12,7 |

| Ro-Ma |

10° |

22,2 |

Summer version |

Ro-Ma 8 |

127 |

22,2 |

20 |

| Ro-Ma |

10° |

22,2 |

Summer version |

Ro-Ma 8 |

150 |

22,2 |

20 |

| Ro-Ma |

10° |

22,2 |

Summer version |

Ro-Ma 8 |

203 |

22,2 |

25,4 |

| Ro-Ma |

10° |

22,2 |

Summer version |

Ro-Ma 8 |

203 |

22,2 |

32 |

| Ro-Ma |

10° |

22,2 |

Winter version |

Ro-Ma 9 |

127 |

22,2 |

12,7 |

| Ro-Ma |

10° |

22,2 |

Winter wersion |

Ro-Ma 9 |

127 |

22,2 |

20 |

| Ro-Ma |

10° |

22,2 |

Winter version |

Ro-Ma 9 |

150 |

22,2 |

20 |

| Ro-Ma |

10° |

22,2 |

Winter version |

Ro-Ma 9 |

203 |

22,2 |

25,4 |

| Ro-Ma |

10° |

22,2 |

Winter version |

Ro-Ma 9 |

203 |

22,2 |

32 |

Grit size

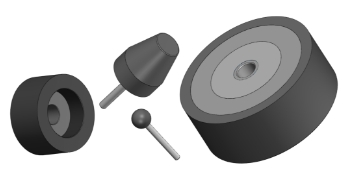

Grinding wheels for sharpening band saws produced by INTER-DIAMENT® are manufactured in various dimensional versions with different working profiles tailored to sharpen saws with different tooth shapes. The working surface of the grinding wheel is covered with high-quality, highly durable borazon grain, providing excellent grinding performance.

The following borazon grain sizes are used:

– B126, B151, for sharpening saws

– B181, B252, for tooth profile correction and potential reprofiling of the saw

Our grinding wheels, produced using the latest technologies, are characterized by a very long working life, leading to significant cost savings for the customer.

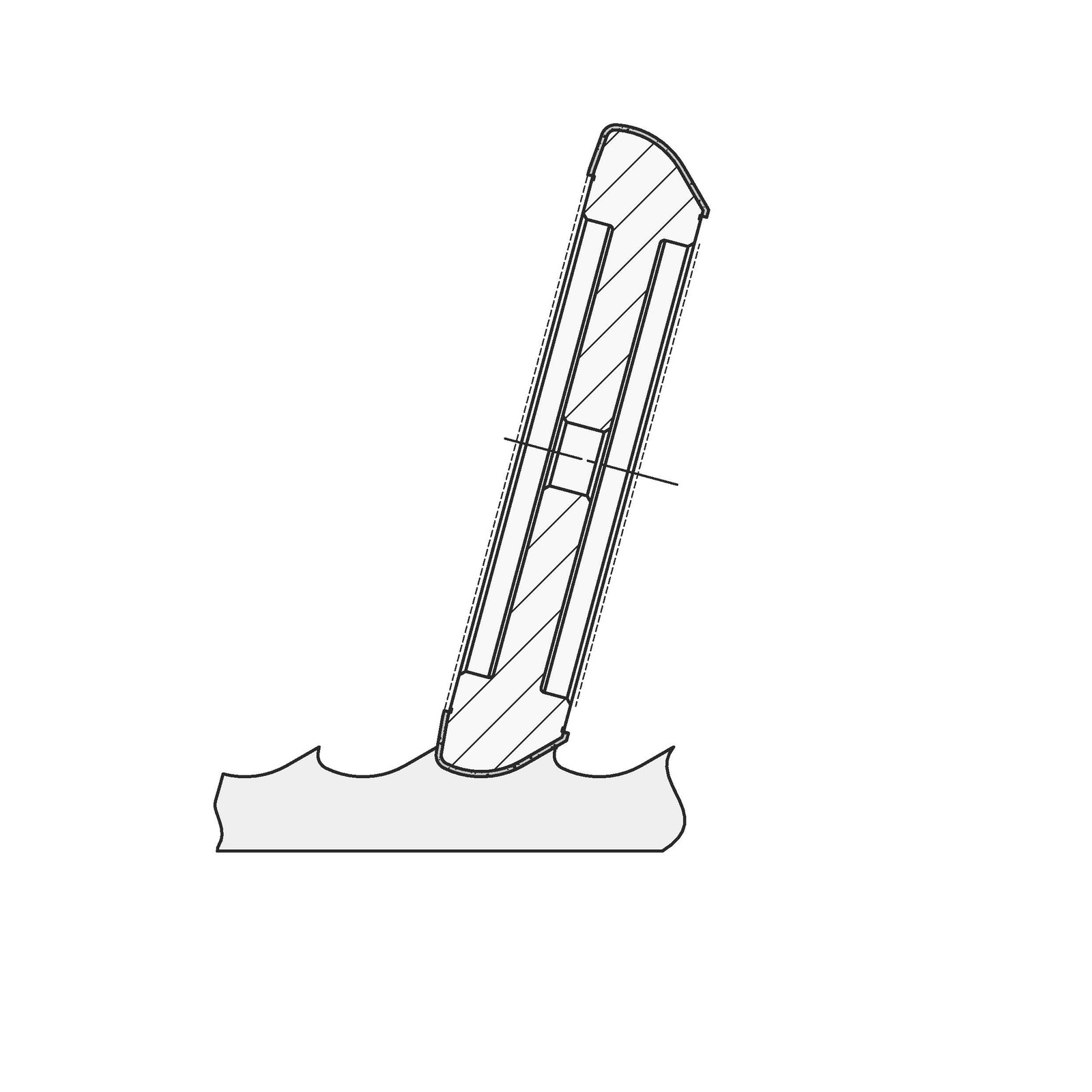

Operating instructions

The optimal peripheral speed of the abrasives mentioned, 20-30 m/s, is crucial for sharpening efficiency and abrasive longevity.

Recommended types of cutting fluid:

– ACP-2-E non-emulsifying – ORLEN

– WECO EP-10 (or EP-15) – PROMASZ

Notes:

It is not recommended to use oil emulsions due to the sensitivity of the borazon grain to water. In low ambient temperatures, it is advisable to heat the machine oil to reduce its viscosity. During the sharpening process, the coolant oil stream should be directed directly onto the grinding wheel (not onto the saw teeth) to remove metal shavings continuously and prevent clogging of the grinding wheel’s working surface. The flow of the cooling oil must be continuous. Periodically, it is advisable to clean the grinding wheel with drive oil. Before starting the sharpening process, check the positioning of the grinding wheel relative to the saw. The grinding wheel should make contact with the saw across its entire circumference on the working part, only reaching the bottom of the saw gullet. The sharpening process should be supervised by the operator, with a particular focus on the effectiveness of cooling with the oil stream

Order example

| Ściernica |

D T H |

Korpus |

Ziarno |

Spoiwo |

Asortyment |

| RO-MA 8 |

128 x 22,2 x 12,7 |

KS |

B151 |

G |

RO-MA 8 128 x 22,2 x 12,7 KS B151 G |

| WM 9/29 |

150 x 22,2 x 20 |

KS |

B181 |

G |

WM 9/29 150 x 22,2 x 20 KS B181 G |

Search

Search Language

Language