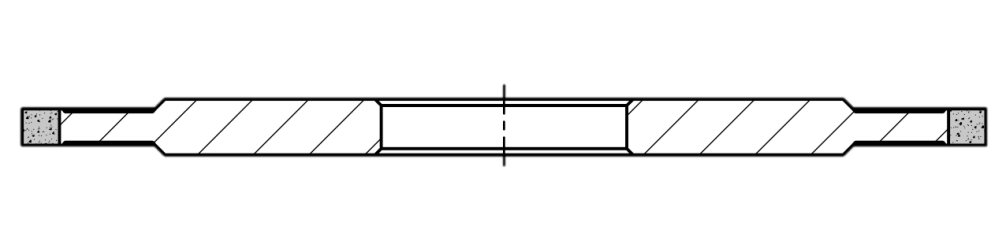

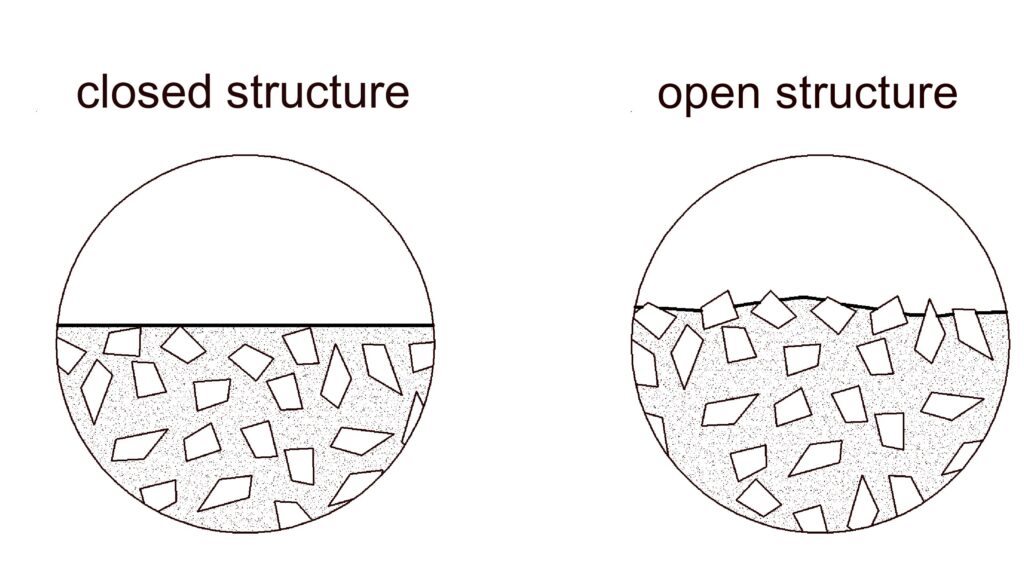

Concentration determines the amount of diamond or boron grain per unit volume of the grinding wheel layer. The standard grain concentration values for resin bonded grinding wheels are shown in the table below.

| Diamond |

Borazon |

| Concentration |

Grain content [carat/cm3] |

Concentration |

Grain content [carat/cm3] |

| K25 |

1,1 |

V60 |

1,05 |

| K50 |

2,2 |

V120 |

2,09 |

| K75 |

3,3 |

V180 |

3,13 |

| K100 |

4,4 |

V240 |

4,18 |

| K125 |

5,5 |

V300 |

5,22 |

The concentration of abrasive grit in the working layer is one of the most important parameters of a grinding wheel. It affects the grinding wheel’s ability to grind, its service life, the temperature of the workpiece, and also the accuracy of the machining. Like any parameter, the concentration should be properly selected to suit the grinding process conditions. It should be remembered that the optimum concentration value depends on the other parameters of the grinding wheel, i.e. grit size, bond hardness, etc.

High concentration (K100, K125; V240, V300) is recommended for:

– high demands on the behaviour of the grinding wheel profile during operation

– low abrasive layer height

– hard bond

– coarse grain

– deep grinding

A standard concentration (K50, K75; V120, V180) is recommended for:

– grinding of planes and cylindrical surfaces

– medium abrasive layer height

– soft bond

– fine grain

A low concentration (K25; V60) is recommended for:

– very wide abrasive layers

– very fine grain

A high grain concentration increases tool life, which is particularly important for contour grinding and for grinding workpieces with very small diameters. The benefits of a high tool life generally offset the higher cost of the tool.

A disadvantage with high grain concentration is the occurrence of higher cutting forces and an increase in the temperature of the machining process. A high concentration of grain is not always the most favourable and technologically best solution, but it certainly requires good cooling.

Search

Search Language

Language