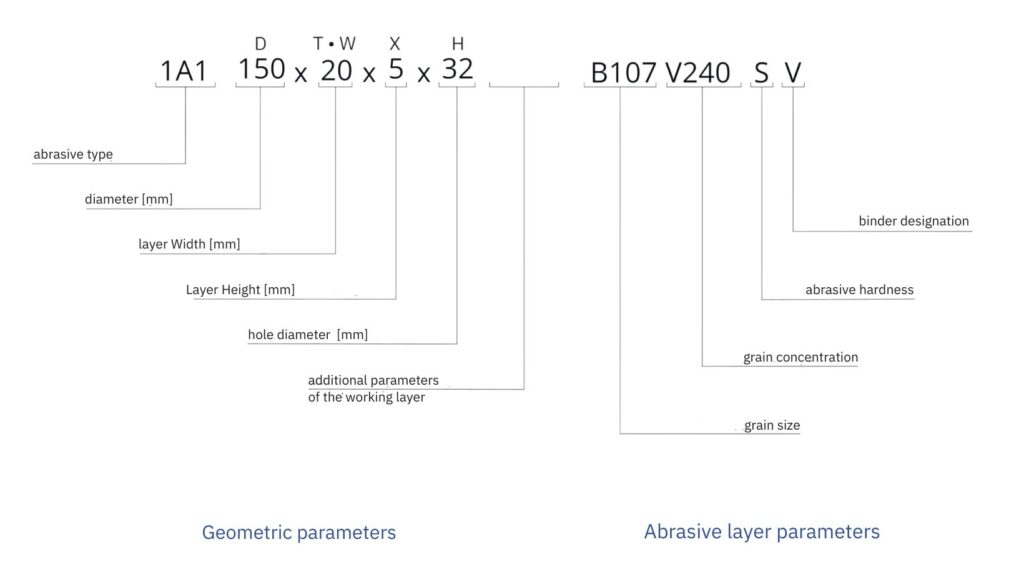

Vitrified bonded CBN grinding wheels are designated according to the following scheme:

The grain size is listed in the table according to the FEPA designation.

The Concetration of the CBN grains of the unit of volume on the working surface of the grinding wheel. A concentration of V240 was taken as the standard value for grain concentration in vitrified bonded grinding wheels. Other concentration values are V180, V300

Storage

Proper storage of grinding wheels keeps them in full working order and is a prerequisite for safe use. Vitrified bonded grinding wheels should be stored at a minimum temperature of 4°C and a maximum relative humidity of 70%.

Mounting

The grinding wheel should be sound-checked before mounting on the grinding machine spindle. A clean sound indicates that there are no internal cracks, while a short frequency-shifting sound occurs when the grinding wheel has internal, often invisible microcracks. Use of such a wheel is not allowed.

Balancing

Before putting a new grinding wheel into service, it should always be carefully balanced to correct manufacturing errors related to its shape and structure. Grinding wheels must be dynamically balanced due to the high speeds used in order to ensure safe operating conditions. Dynamic balancing makes it possible to achieve many times smaller vibration amplitudes than static balancing. Balancing directly on the grinder using specialised equipment such as a VibroDAQ balancing system is recommended.

Dressing

A prerequisite for the correct grinding process is that the shape of the grinding wheel surface is adapted to the task at hand. Dressing of grinding wheels is used to give the desired shape to the working surface of a new grinding wheel or to restore its original cutting properties during grinding operations.

Grinding speed

During grinding operations, an important role is played by grinding speed which is the linear speed of the grains on the grinding surface. The correct selection of this speed depending on the type of material being processed and the type of processing is a crucial issue. The advantage of vitrified CBN grinding wheels is the significantly lower heat generated during grinding compared to conventional grinding wheels, which allows for particularly high grinding speeds to be used without fear of thermal damage to the workpiece surface. With this in mind, the use of high grinding speeds is by all means beneficial, but requires careful balancing of the grinding wheels and the use of high-powered machine tools.

Corrective measures

A properly selected vitrified grinding wheel requires only minimal corrective measures during use, which include improving the working profile and sharpening.

The abrasive grit wears down during prolonged use of the grinding wheel. In addition, some of the spoil accumulates in the natural pores of the grinding wheel, causing it to lose its cutting properties. Dressing the wheel restores its original cutting properties and working efficiency.

If possible, please specify the type of material and type of processing in your order as well as the operating conditions and type of machinery the wheels will be used on. This will allow us to adapt the wheel as closely as possible to your needs.

If you are interested in a grinding wheel not found in our offer, we can custom manufacture one for you by special order. This page consist some of the most popular products from our offer.