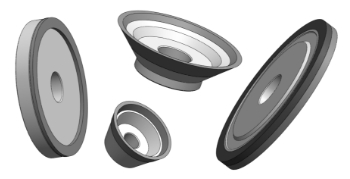

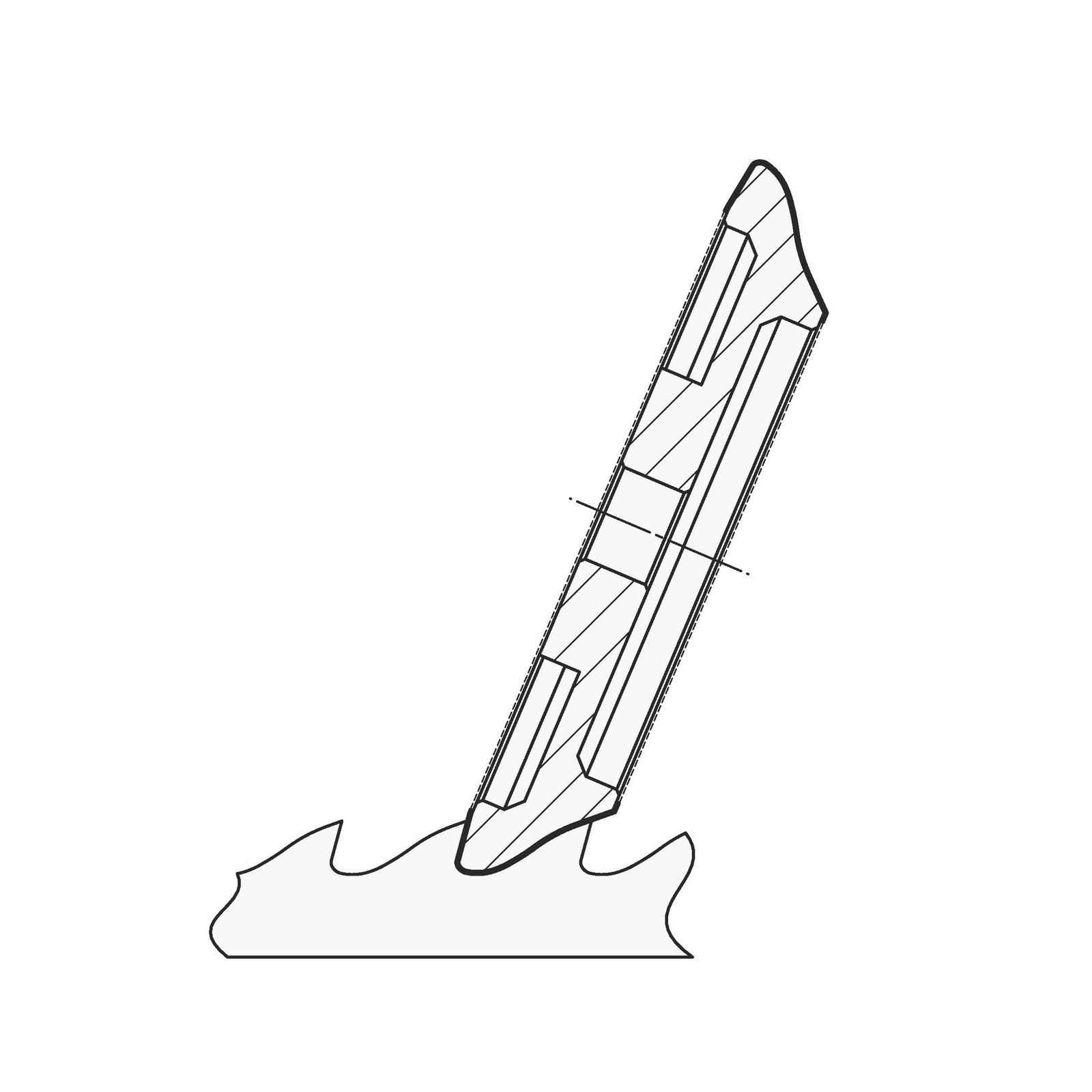

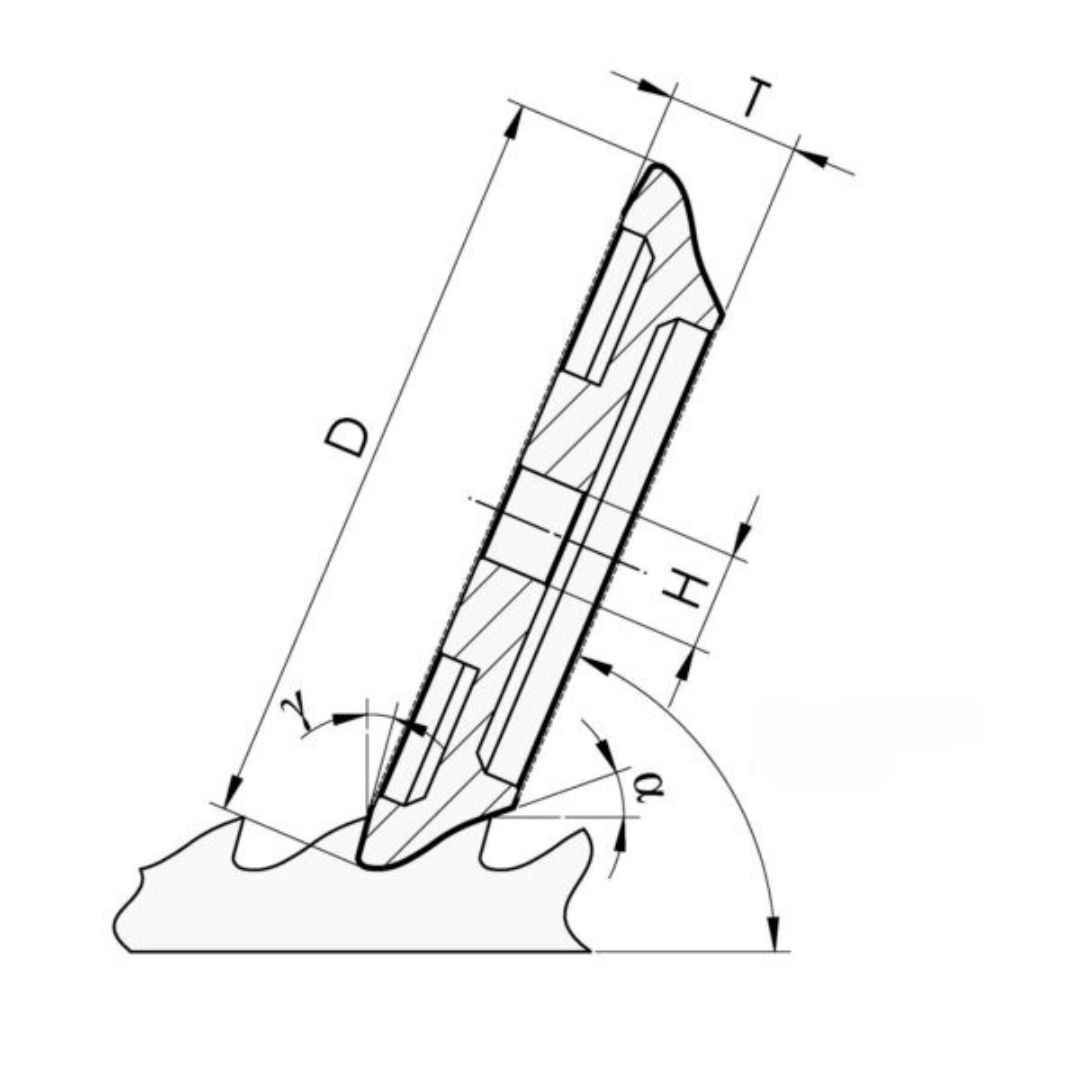

Profiled borazon grinding wheels PT with a galvanic bond are designed for sharpening circular saw blades used in the woodworking and sawmill industry. These grinding wheels are primarily produced in diameters ranging from ø 200 to ø 250.

Thanks to the precise adaptation of the grinding wheel profile to the tooth shape, high repeatability of the tooth geometry is achieved after sharpening, ensuring a long saw blade lifespan.

Search

Search Language

Language