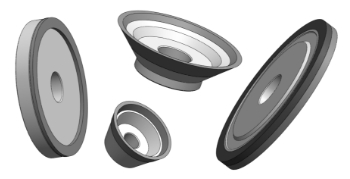

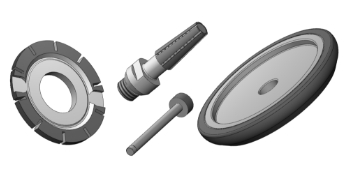

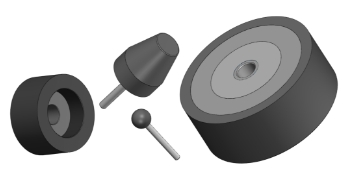

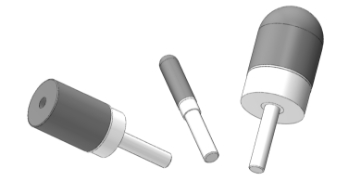

These grinding wheels are made from a super-hard CBN abrasive filled with a ceramic bond. High-performance grinding wheels are used for machining super-hard materials requiring high accuracy and high classes of surface smoothness. Vitrified bonded CBN grinding wheels exhibit a significant advantage over conventional tools in high-performance grinding processes. The physical properties of CBN (hardness, abrasion, and heat resistance) in combination with the characteristics of the vitrified bond (hardness, brittleness, porous tool structure) allow more efficient cutting of the workpiece material and high quality grinding.

Cubic boron nitride (CBN) is referred to as a super-hard material due to its significantly higher hardness compared to traditional abrasives such as aluminium oxide (Al2O3), also known as corundum, or silicon carbide (SiC), also known as carborundum.

CBN is used in grinding processes where the priority is to achieve excellent surface quality with high machining efficiency.

The main advantages of using abrasive tools made of CBN are as follows:

– long service life due to the preservation of the tool profile

– short processing times

– shorter auxiliary times due to fewer tool changes

– elimination of thermal damage to workpiece surfaces due to lower grinding temperatures

– maintenance of working profile

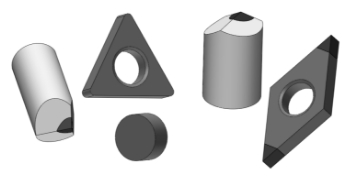

CBN abrasive tools are designed for machining:

– high-speed steels (HSS)

– tool steels

– steels for carburising

– bearing steels

– stainless and high-alloy steels with a hardness of at least 55HRC

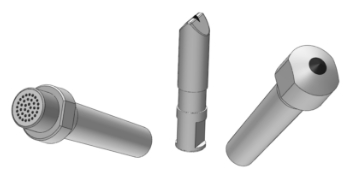

Grinding wheels can be made on a vitrified or metallic body. A metallic body should be used for diameters above ø 300 as it is more homogeneous and allows operation at higher speeds.

Search

Search Language

Language