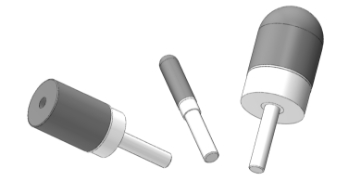

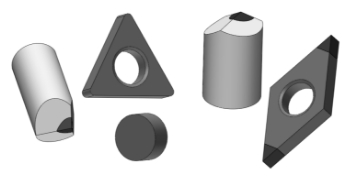

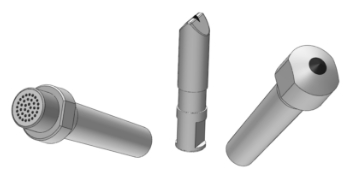

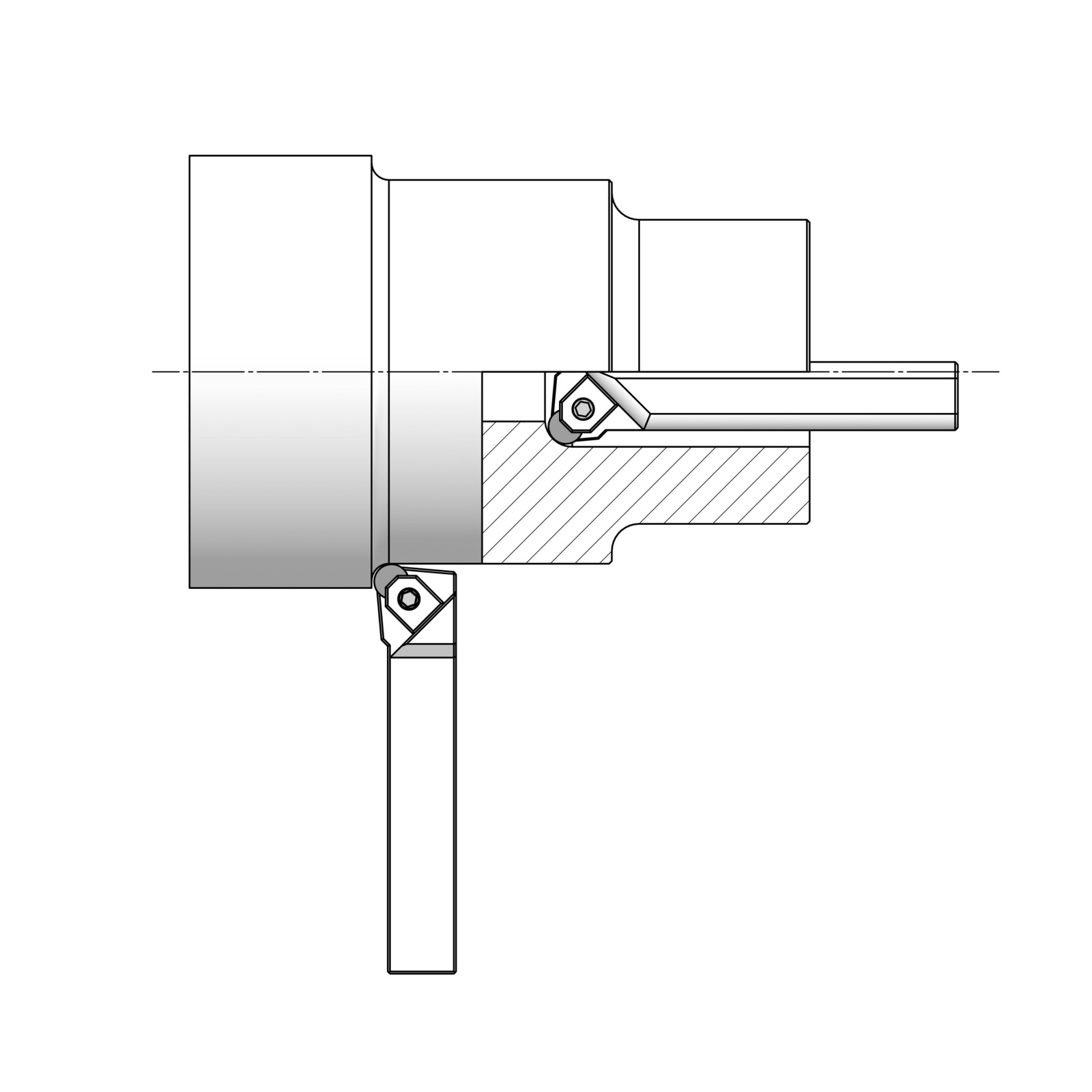

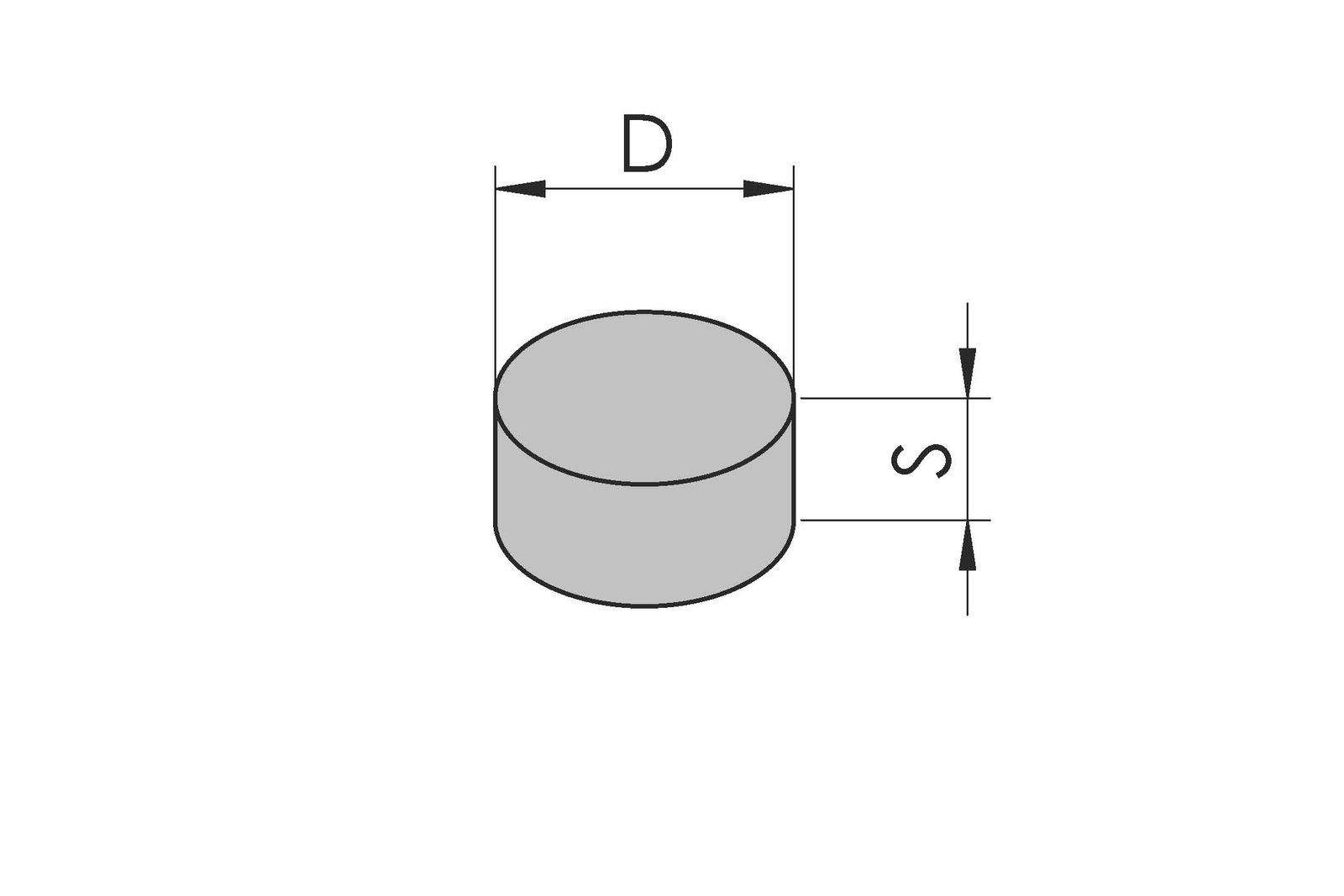

RNMN composite cutting inserts are designed for machining:

– hardened steels

– cast iron

– carbides

– non-ferrous metals and their alloys

The use of composite cutting inserts is particularly recommended for difficult cutting conditions. Thanks to their high impact resistance, they are ideal for applications such as rough machining of cast parts and also precision finishing.

The cutting inserts are made of super-hard composites based on boron nitride; these materials have very high hardness (about 2÷4 times the hardness of carbides) and thermal strength, and do not react chemically with compounds formed with iron and carbon.

Advantages of composite cutting inserts:

– excellent cutting properties

– high surface quality

– high performance

– versatility of application

– long service life

– low processing costs

Search

Search Language

Language